Latest News

Visit to see 19B's Boiler in Wales - from "Fuzz" Jordan

We said we would provide (at least) an annual opportunity to come and see the engine. You will know that the new boiler is currently under construction in the Ffestiniog Railway’s Boston Lodge Works whilst the chassis remains at Statfold. As the boiler is pretty much the story of the moment, we thought a visit there would create most interest.

As it is a fair way for most of us to travel to Porthmadog, it would be a shame to visit the TLC (top left-hand corner) of Wales without having a train ride or two, we have made a weekend of it, with the opportunity to take return journeys on both the Ffestiniog Railway (Porthmadog to Blaenau) and the Welsh Highland Railway (Porthmadog to Caernarfon) at discounted rates. There is also the opportunity to visit Boston Lodge to see the new boiler under construction, and we hope we’ll be able to answer all your questions!

As Boston Lodge is a working engineering establishment, we regret the FfR has some restrictions to admission, as follows:

-

Due to the uneven ground and the amount of walking involved, the tour is not accessible to wheelchair users or people who are not fully mobile without assistance. For your own safety and comfort, tour participants must be able to stand and walk for the two-hour duration unaided. Your sight must be sufficient to see potential dangers yourself. Accessibility is under constant review.

-

Dogs are not allowed in Boston Lodge.

-

Please wear warm clothes and bring a waterproof as the weather can be unpredictable. Stout shoes, preferably walking boots, must be worn. Anyone wearing sandals or open-toed shoes will not be allowed on the tour.

-

There are no café facilities at Boston Lodge. Spooner’s Café & Bar at Harbour Station gives you an opportunity to grab a drink or enjoy a delicious meal before or after any tour.

The plan for the weekend is as follows:

Saturday 11 April. Meet at Porthmadog Harbour station at 1015 to catch the 1045 ‘Harbourmaster’ train to Caernarfon, a 2½ hour journey. You’ll have about 1 ½ hours to wander round this historic town and Castle, before boarding the return train to Porthmadog. In the evening, we will try and organise options for group dinners, but exact arrangements will depend on numbers wishing to attend. Please let us know if you are interested.

Sunday 12 April. Meet at Porthmadog Harbour station at 1015 to catch the 1040 ‘Mountain Spirit’ train to Blaenau Ffestiniog with a journey time of about seventy minutes. There’s then time for a brief look round the town before returning to Porthmadog, arriving at lunch time. There will be time for some refreshments at Spooners’ Bar in Harbour Station before we cross to Boston Lodge to see the railway works and inspect our new boiler. (Please note that you will need you own transport to cross from Porthmadog to Boston Lodge, or the walk is about one mile).

Train fares

The normal return fare from Porthmadog to Caernarfon is £72 second class and £108 first class. We are offering fares of £65 second class and £99 first class.

The normal return fare from Porthmadog to Blaenau Ffestiniog is £49.75 second class and £75.50 first class. We are offering fares of £45 second class and £68 first class.

As an additional bonus, if you book BOTH trains, the combined fares would be £100 second class or £150 first class.

If you are an Annual Member of the Festiniog Railway Society (FRS), you are entitled to a free second class ticket from Porthmadog to Blaenau. Subject to availability, Life Members are entitled to a free first class ticket. All FRS members can claim privilege rate on a second class Welsh Highland return ticket.

Likewise, if you are an Annual Member of the Cymdeithas Rheilffordd Eryri (Welsh Highland Railway Society), you are entitled to a free second class ticket from Porthmadog to Caernarfon. Subject to availability, Life Members are entitled to a free first class ticket. All WHRS members can claim privilege rate on the Ffestiniog

To clarify the availability rule, it has long been the custom and practice, where the first class on any train is over-subscribed, those travelling on free first class tickets are expected to downgrade to second class thus allowing the railway to retain another paid fare from a first class passenger. We will be honouring this convention.

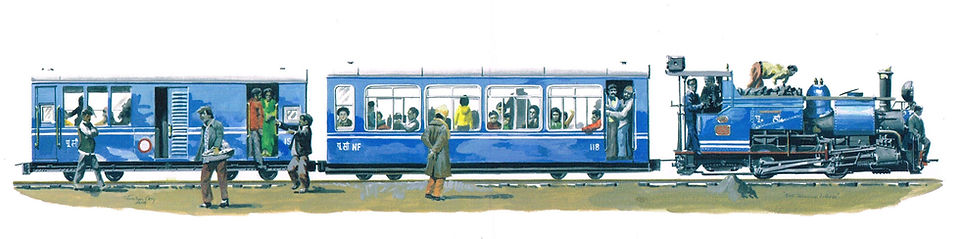

Painting by Jonathan Clay